We are developing a scalable bioreactor system for solid state fermentation (SSF). This fermentation platform technology aims to increase circularity within the food and agricultural sector by upcycling organic waste products.

SSF is an old technology mainly manually handled. Our technology is based on automatically controlled, AI-based technology, that advance the use of SSF with better utilization of existing resources. This will result in price-competitive sustainably produced compounds for the industry and society.

SSF description

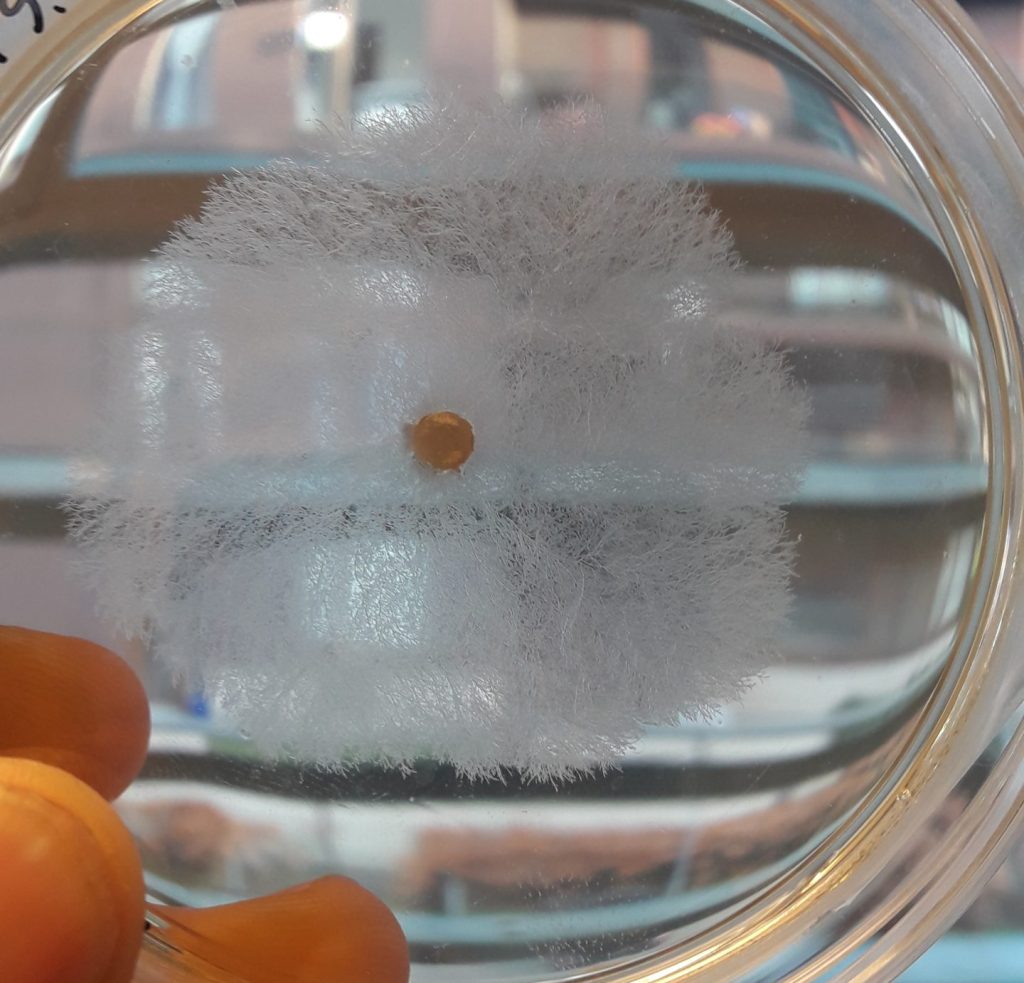

Solid-state fermentation (SSF) is a well-known process developed and adopted in human society for the production of traditional foods such as cheese, bread, soy sauce, and tempeh. It is also being explored for new applications, including the production of enzymes, meat alternatives, and bio-based building materials. With increasing concerns about climate change and environmental deterioration, the renewal of SSF technology aims to transform human life in a more sustainable and environmentally friendly manner. SSF plays a pivotal role in creating a closed-loop system in the bioeconomy by recycling and upcycling industrial side streams into value-added products.

Compared to submerged or liquid fermentation, SSF promotes the utilization of organic solid materials in a cost-effective and sustainable manner. It offers simple implementation, minimal water requirements, less wastewater treatment, and low energy consumption. Moreover, the direct application of fungi in SSF creates a high synergy between the natural traits of fungal colonization and substrate utilization under controlled cultivation conditions. This synergy helps develop the desired structural matrix of fermented products (e.g., meat-like texture, durable materials) and improves the production of fungal metabolites (e.g., enzymes and mycoprotein).

Challenges and our solutions

Due to limited visibility of substrates and microorganisms, lack of agitation, and the absence of non-destructive monitoring approaches, scaling up solid-state fermentation (SSF) is challenging, especially in achieving homogeneous fermentation conditions and consistent product quality. To date, the success of large-scale SSF has been limited to specific substrates and microorganisms, with fermentation conditions and setups determined empirically and not fully applicable to new process development with variations in the composition of the substrate and fungal physiology.

Myco4food aims to develop innovative platform technology to address these challenges in large-scale SSF. Our technology comprises two major components:

1. Novel Bioreactor Design: This includes advanced sensors and control units to achieve comprehensive acquisition of fermentation data, homogeneous fermentation conditions, and effective microclimate control.

2. Backend System: This system processes data collected during SSF to predict fungal physiological variables and adjust operational parameters through AI-assisted control system in a real-time manner to optimize fermentation performance and minimize production of unwanted metabolites or sporulation.

Our modular design allows customization to meet the requirements of different processes, providing enhanced compatibility and scalability.

Myco4Food is on the path to transforming how we utilize organic waste materials – to produce the protein ingredients of the future.